Last time I blogged (a month ago), you got the No-photo report (with photos), so today I follow up with ‘Two months’ work in twenty photos’ (which may just be twenty-one!), starting with what I’d already described and partially shown there:

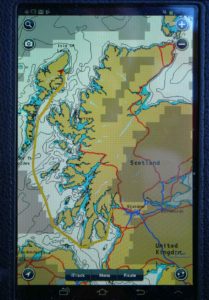

The overhauled seacocks are back together onboard, and new heads, water pump, water filler, galley tap, chart table support block and replacement galley shelf edges all fitted. The folding chart table (which you won’t see varnished and refitted for a while because I’m currently concentrating on immovable bits) has gained a nice teak handle I found in my loft, and I’m also replacing the ugly alloy handles on the heads door with teak rings. The nav. station bulkhead has cutouts for switch panels and stereo, and varnishing the permanently-attached interior woodwork is nearly done, with just a couple more coats to go next weekend before we can get rewiring and relining the boat.

Which, since you’ve already seen the new galley shelf edges and refitted seacocks, properly starts with the heads and, as promised, the cardboard mock Jabsco (which I made to check the standard unit would fit and we didn’t need the compact):

Next, the water pump, filler, other galley stuff and chart table support block (with thanks to Peter Watt for the iroko for the shelf edges and block as well as some other parts we’ve yet to make). Note also the new hull lining (about which more below) visible here and in the nav. station shots:

The two sections of the folding chart table are nearly finished, with five of a probable six coats of varnish to the outside surfaces done here and the sixth completed since taking the photos this afternoon (some woodwork has received up to nine or ten coats, but I’m treating six as my baseline for most things). Note the new handle on the main body and fiddles on the lid:

And here are the teak rings set into the heads door. You’d normally fit just one of these for a locker door, but I’ve used two back-to-back because both sides will show, cutting down the insert tubes to fit them to the 12mm thickness of the door. Now just waiting for some more teak filler to fill the remaining unwanted holes before varnishing:

Twig’s fitted the switch panels, run most (all?) of the necessary wiring through conduit, and made a tidy job of connecting switch panels to fuse box. The third cutout in the bulkhead is for the stereo, which we’ve got but haven’t fitted yet:

We’d decided long ago to re-line the boat with 4mm polypropylene carpet instead of something like the original ‘Mural Mousse’ (some kind of vinyl-type thing?), and went for two-tone grey, choosing the slightly darker shade (‘smoke’) for the topsides and lighter one (white-grey) for the coachroof sides and deckhead (NB Fly’s current bunk cushion covers are the same blue-grey herringbone pattern as my sofa):

And the darker grey is all done bar some finishing of edges etc., with Drew Mcfarlane-Slack coming up to get it started with Twig, then Twig continuing with some assistance from me:

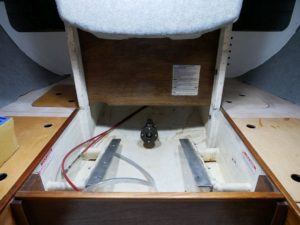

The engine bay has been cleaned and awaits engine refitting:

And the new heads window is done at last, completing a clean sweep of previously leaky forehatch (2011) and main windows (2016). This was made by Twig in my workshop with my tools on Christmas Eve, which we’d chosen as cold but dry, but turned out so cold we had to put up a second ladder because the decks were untenably slippy:

So much work has been done and much continues, but we’re undoubtedly starting to see the fruits of all that endless careful preparation, which takes up so much time without things necessarily looking better. On which note, make no mistake, this is (internally at least) a total refit I’d guess to be pretty well equivalent to building the boat from the original kit. There are some things there we’ve not had to do, but other non-kit parts (i.e. original Hunter structure) we’ve had to repair or rebuild. But have to say I’m sitting here looking at the photos I took today in the boat I’ve spent so much of the past eighteen months working on and thinking just ‘wow!’ :-)