While I’ve spent many hours (most weekday evenings and all weekend) on Fly since last weekend’s blog, more of that time’s probably been spent thinking through tricky stuff and making sure I get it right than actually doing. So no prizes for speed with what you’re about to see, but still considerable satisfaction on not only avoiding most of the potential banana skins but also making a good job of some tricky parts…

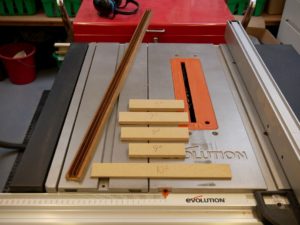

Let’s start with my new mount for Fly’s top galley door track, which brings the tracks properly parallel by allowing for deck rise and camber when the standard method of fixing doesn’t. To do this I had to establish both angles and cut some test pieces to try in place, knocking up a taper jig for the table saw along the way and working out how to cut the angles for rise (about 10mm over the galley width) and camber (6° rather than the 10° you see set up in the first two photos) in separate passes because the saw blade tilts the wrong way to do both together, but happy to say I’ve got this piece dead right:

Next (well, not actually next because I also made some other small parts you don’t see here) we come to my folding leg for the folding chart table, which looks so simple when done, but isn’t because you have to consider:

- What length should it be to keep the table true when you’re working with one corner unsupported?

- Where should it meet the bunk top fore and aft and where should it be attached to the table to keep it vertical in both planes?

- Is it going to be strong enough (fit for purpose) both in itself and how it’s attached?

- Will it fold up neatly out of the way?

- What happens if someone knocks it from an unexpected direction?

- How do you hold all of this where you want it to jig it up for drilling?

- And did you get it right?

Now, what you see here isn’t quite finished because it still needs corners rounding, varnishing, a longer bolt, penny washer between leg and table, and a locating socket bonded to the bunk top, but I think I did OK:

Two more things worth noting about the chart table before I forget are that 1. I’ve fitted my final choice of catches (toggle latches from China as the most attractive and size-appropriate option turned up by hours of Googling), and 2. I can’t remember whether we’d previously noted that the new lower nav. shelf restricts the lid opening angle to c.45°, but it doesn’t really matter because that’s probably far enough anyway and we can get quite a lot more by chamfering the bottom of its edge piece if necessary!

And so to yet more speaker enclosure tweaks. I wanted to add cosmetic trim pieces (same way I still plan to finish most visible lining edges) to the corners between coachroof sides and main bulkhead to cover the port-side wires and some over-neat starboard-side finishing, which wasn’t difficult at all:

But then had to tweak the outside bottom corners of the speaker boxes to fit the trim, which could so easily have resulted in messing them up now, but didn’t:

And that’s about it for now, except to show you bottom galley track fixing, take two, where take one had assumed I needed to fix the track as far out as possible for vertical doors to clear the top shelf at the main bulkhead end, but I’d not liked what I got so reevaluated carefully: